MiiCraft provides users with a variety of materials for different application scenarios, such as impact and compressive strength, tough and durable materials. The printed parts can be used directly and have good performance.

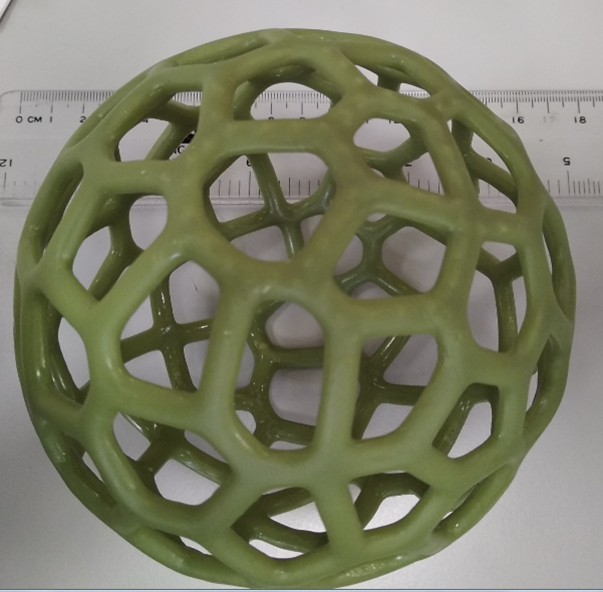

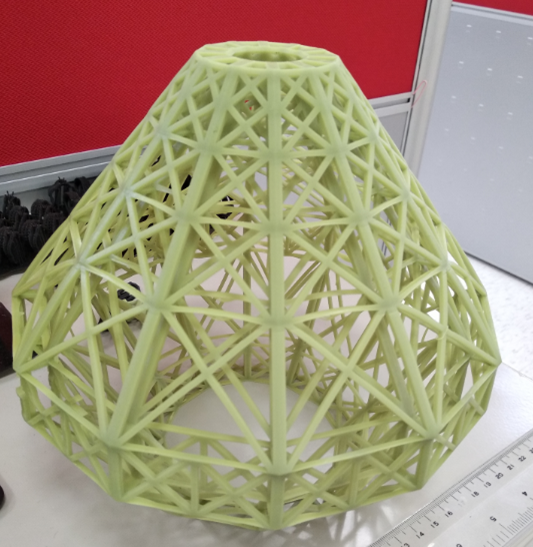

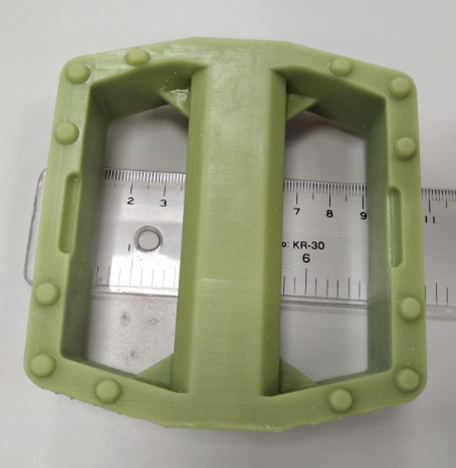

MiiCraft provides customers with precise and stable printing quality to facilitate mass production of products. The ultimate resolution and high-precision optical engine can print incredible complex shapes, curved circular holes, and other product details.

From prototype design to functional terminal components, you can now easily print terminal components in just a few hours. Stable printing quality and faster printing speed ensure more efficient production. Reduce the initial research and development costs, and accelerate the speed of product innovation iteration.

Industrial solutions

MiiCraft industrial solutions provide reliable parameters and stable printing materials

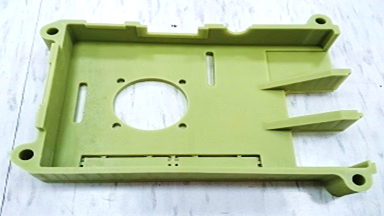

No. Model resin printing parameters post-processing model image 1Profession 250BV-023 Layer thickness: 100um Speed: slow curing time: 13.5s Gap: 0mm Base curing: 35s Number of base layers: 1 Buffer layer: 6 Washing: Alcohol curing Energy: 30mw/cm2 Post curing time: 600s 2Profession 250BV-023 Layer thickness: 100um Speed: slow curing time: 13.5s Gap: 0mm Base curing: 35s Number of base layers: 1 Buffer layer Layer: 8 Washing: Alcohol post curing Energy: 30mw/cm2 Post curing Time: 600s

2Profession 250BV-023 Layer thickness: 100um Speed: slow curing time: 13.5s Gap: 0mm Base curing: 35s Number of base layers: 1 Buffer layer Layer: 8 Washing: Alcohol post curing Energy: 30mw/cm2 Post curing Time: 600s 3Profession 250BV-023 Layer thickness: 100um Speed: Slow curing Time: 13.5s Gap: 0mm Base curing: 35s Number of base layers: 1 Buffer layer: 10 Washing: Alcohol post curing Energy: 30mw/cm2 Post curing Time: 600s

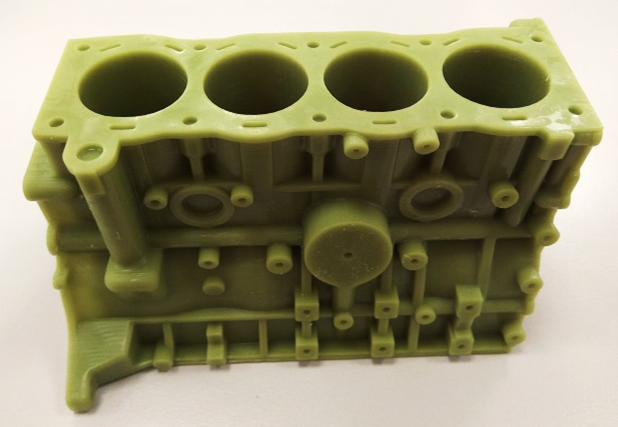

3Profession 250BV-023 Layer thickness: 100um Speed: Slow curing Time: 13.5s Gap: 0mm Base curing: 35s Number of base layers: 1 Buffer layer: 10 Washing: Alcohol post curing Energy: 30mw/cm2 Post curing Time: 600s 4Ultra 150BV-022 Layer thickness: 100um Speed: Slow curing Time: 13.5s Gap: 0mm Base curing: 35s Number of base layers: 1 Buffer layer: 10 Washing: Alcohol post curing energy: 30mw/cm2 Post curing time: 600s

4Ultra 150BV-022 Layer thickness: 100um Speed: Slow curing Time: 13.5s Gap: 0mm Base curing: 35s Number of base layers: 1 Buffer layer: 10 Washing: Alcohol post curing energy: 30mw/cm2 Post curing time: 600s 5Lesson 250BV-022 Layer thickness: 50um Speed: Normal curing time: 2s Gap: 0 Base curing: 15s Number of base layers: 1 Buffer layer: 4 Washing: Alcohol post curing energy: 30mw/cm2 Post curing time: 600s

5Lesson 250BV-022 Layer thickness: 50um Speed: Normal curing time: 2s Gap: 0 Base curing: 15s Number of base layers: 1 Buffer layer: 4 Washing: Alcohol post curing energy: 30mw/cm2 Post curing time: 600s 6Lesson 250BV-022 Layer thickness: 50um Speed: Normal curing time: 2s Gap: 0 Base curing: 18s Number of base layers: 1 Buffer layer: 4 Washing: Alcohol post curing energy: 30mw/cm2 Post curing time: 600s

6Lesson 250BV-022 Layer thickness: 50um Speed: Normal curing time: 2s Gap: 0 Base curing: 18s Number of base layers: 1 Buffer layer: 4 Washing: Alcohol post curing energy: 30mw/cm2 Post curing time: 600s 7Lesson 250BV-022 Layer thickness: 100um Speed: Normal curing time: 3.5s Gap: 0 Base curing: 18s Number of base layers: 1 Buffer layer: 4 Washing: Alcohol post curing energy: 30mw/cm2 Post curing time: 900s

7Lesson 250BV-022 Layer thickness: 100um Speed: Normal curing time: 3.5s Gap: 0 Base curing: 18s Number of base layers: 1 Buffer layer: 4 Washing: Alcohol post curing energy: 30mw/cm2 Post curing time: 900s 8Lesson 250BV-022 Layer thickness: 100um Speed: Normal curing time: 3.7s Gap: 0 Base curing: 18s Base layer Number: 1 Buffer layer: 4 Washing: Alcohol post curing Energy: 30mw/cm2 Post curing time: 900s

8Lesson 250BV-022 Layer thickness: 100um Speed: Normal curing time: 3.7s Gap: 0 Base curing: 18s Base layer Number: 1 Buffer layer: 4 Washing: Alcohol post curing Energy: 30mw/cm2 Post curing time: 900s 9Lesson 250BV-022 Layer thickness: 100um Speed: Normal curing time: 3.4s Gap: 0 Base curing: 16s Base layer number: 1 Buffer layer: 4 Washing: Alcohol post curing Energy: 30mw/cm2 Post curing time: 600s

9Lesson 250BV-022 Layer thickness: 100um Speed: Normal curing time: 3.4s Gap: 0 Base curing: 16s Base layer number: 1 Buffer layer: 4 Washing: Alcohol post curing Energy: 30mw/cm2 Post curing time: 600s 10Lesson 250BV-022 Layer thickness: 100um Speed: Slow curing time: 2.5s Gap: 0 Base curing: 15s Base Bottom layer: 1 Buffer layer: 4 Washing: Alcohol curing energy: 30mw/cm2 Post curing time: 600s

10Lesson 250BV-022 Layer thickness: 100um Speed: Slow curing time: 2.5s Gap: 0 Base curing: 15s Base Bottom layer: 1 Buffer layer: 4 Washing: Alcohol curing energy: 30mw/cm2 Post curing time: 600s 11Lesson 250BV-022 Layer thickness: 100um Speed: Slow curing time: 2.5s Gap: 0 Base curing: 20s Base layer number: 1 Buffer layer: 8 Washing: Alcohol curing energy: 30mw/cm2 Post curing time: 600s

11Lesson 250BV-022 Layer thickness: 100um Speed: Slow curing time: 2.5s Gap: 0 Base curing: 20s Base layer number: 1 Buffer layer: 8 Washing: Alcohol curing energy: 30mw/cm2 Post curing time: 600s 12Lesson 250BV-022 Layer thickness: 100um Speed: Slow curing time: 2.5s Gap: 0 Base curing: 1 5s Base layer: 1 Buffer layer: 6 Washing: Alcohol curing energy: 30mw/cm2 Post curing time: 900s

12Lesson 250BV-022 Layer thickness: 100um Speed: Slow curing time: 2.5s Gap: 0 Base curing: 1 5s Base layer: 1 Buffer layer: 6 Washing: Alcohol curing energy: 30mw/cm2 Post curing time: 900s 13Ultra 125BV-022 Layer thickness: 50um Speed: Slow curing time: 1.2s Gap: 0 Base curing: 15s Base layer: 1 Buffer layer: 4 Washing: Alcohol curing energy: 30mw/cm2 Post curing time: 300s

13Ultra 125BV-022 Layer thickness: 50um Speed: Slow curing time: 1.2s Gap: 0 Base curing: 15s Base layer: 1 Buffer layer: 4 Washing: Alcohol curing energy: 30mw/cm2 Post curing time: 300s 14Ultra 150BV-022 Layer thickness: 50um Speed: Slow curing time: 1.5s Gap: 0 Base curing: 15s Base Bottom layer: 1 Buffer layer: 4 Washing: Alcohol post curing energy: 30mw/cm2 Post curing time: 600s Total number of layers: 820 Time: 4hr30

14Ultra 150BV-022 Layer thickness: 50um Speed: Slow curing time: 1.5s Gap: 0 Base curing: 15s Base Bottom layer: 1 Buffer layer: 4 Washing: Alcohol post curing energy: 30mw/cm2 Post curing time: 600s Total number of layers: 820 Time: 4hr30 15 Ultra 150BV-022 Layer thickness: 50um Speed: Slow curing time: 1.4s Gap: 0 Base curing: 12s Base layer: 1 Buffer layer: 4 Washing: Alcohol post curing energy: 30mw/cm2 Post curing time: 480s

15 Ultra 150BV-022 Layer thickness: 50um Speed: Slow curing time: 1.4s Gap: 0 Base curing: 12s Base layer: 1 Buffer layer: 4 Washing: Alcohol post curing energy: 30mw/cm2 Post curing time: 480s 16 Ultra 150BV-022 Layer thickness: 50um Speed: Slow curing time: 1.4s Gap: : 0 Base curing: 15s Number of base layers: 1 Buffer layer: 4 Washing: Alcohol post curing Energy: 30mw/cm2 Post curing time: 300s

16 Ultra 150BV-022 Layer thickness: 50um Speed: Slow curing time: 1.4s Gap: : 0 Base curing: 15s Number of base layers: 1 Buffer layer: 4 Washing: Alcohol post curing Energy: 30mw/cm2 Post curing time: 300s 17Teaching 250BASF X004M Layer thickness: 50um Speed: Slow curing time: 3.6s Gap: 0 Base curing: 18s Number of base layers: 1 Buffer layer: 4 Washing: Alcohol post curing Energy: 30mw/cm2 Post curing time: 900s

17Teaching 250BASF X004M Layer thickness: 50um Speed: Slow curing time: 3.6s Gap: 0 Base curing: 18s Number of base layers: 1 Buffer layer: 4 Washing: Alcohol post curing Energy: 30mw/cm2 Post curing time: 900s 18Teaching 250BASF X004M Layer thickness: 50um Speed: Slow curing time : 3.6s Gap: 0 Base Curing: 18s Number of Base Layers: 1 Buffer Layer: 4 Washing: Alcohol Post Cure Energy: 30mw/cm2 Post Cure Time: 1200s

18Teaching 250BASF X004M Layer thickness: 50um Speed: Slow curing time : 3.6s Gap: 0 Base Curing: 18s Number of Base Layers: 1 Buffer Layer: 4 Washing: Alcohol Post Cure Energy: 30mw/cm2 Post Cure Time: 1200s 19Lesson 250BASF X004M Layer Thickness: 50um Speed: Slow Cure Time: 3s Gap: 0 Base Curing: 15s Number of Base Layers: 1 Buffer Layer: 10 Washing: Alcohol Post Cure Energy: 30mw/cm2 Post Cure Time: 600s

19Lesson 250BASF X004M Layer Thickness: 50um Speed: Slow Cure Time: 3s Gap: 0 Base Curing: 15s Number of Base Layers: 1 Buffer Layer: 10 Washing: Alcohol Post Cure Energy: 30mw/cm2 Post Cure Time: 600s 20Lesson 250BASF X004M Layer Thickness: 50um Speed: Slow Slow curing time: 2.8 seconds Gap: 0 Base curing: 15 seconds Number of base layers: 1 Buffer layer: 8 Washing: Alcohol curing Energy: 30mw/cm2 Post curing time: 600 seconds Total number of layers: 440 Time: 2 hours 20

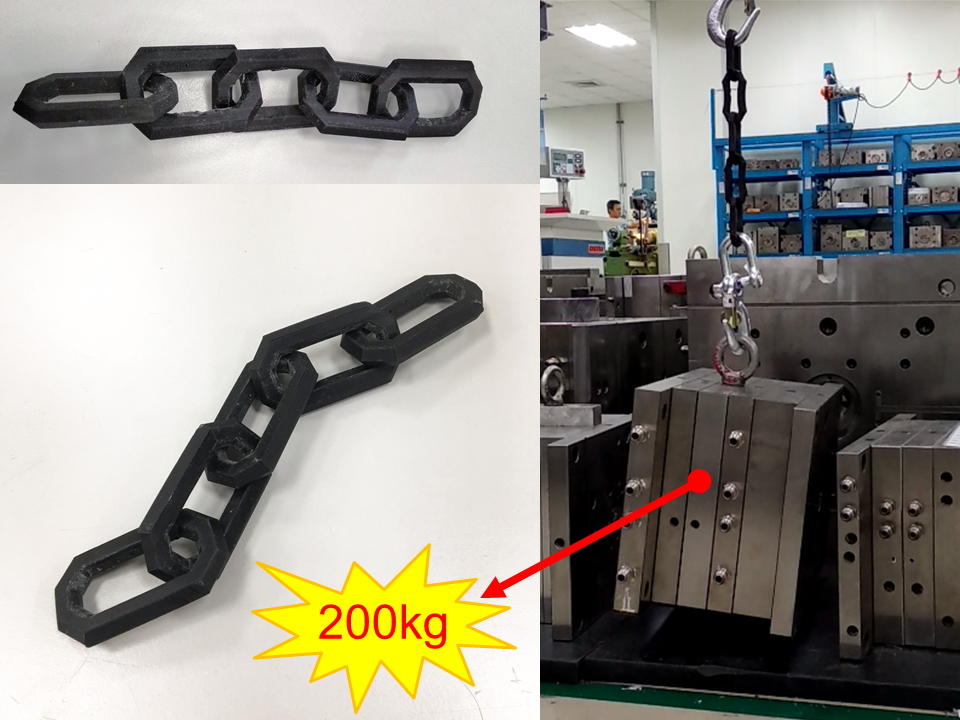

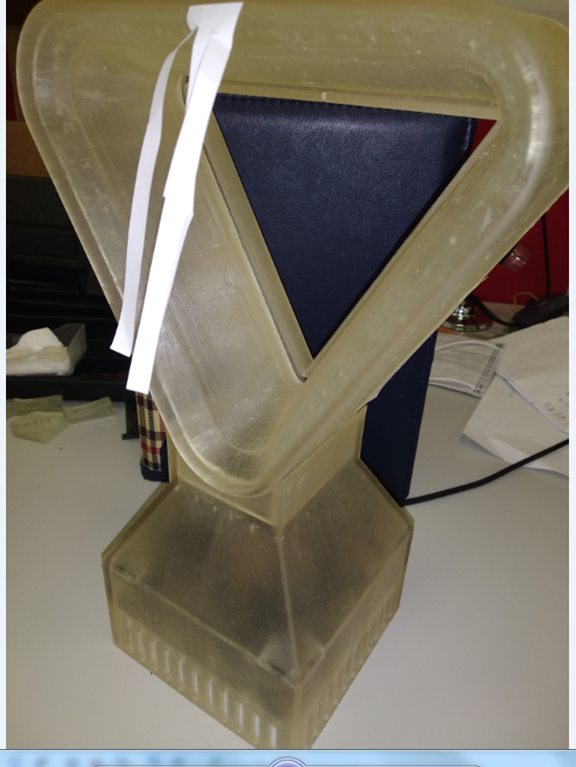

20Lesson 250BASF X004M Layer Thickness: 50um Speed: Slow Slow curing time: 2.8 seconds Gap: 0 Base curing: 15 seconds Number of base layers: 1 Buffer layer: 8 Washing: Alcohol curing Energy: 30mw/cm2 Post curing time: 600 seconds Total number of layers: 440 Time: 2 hours 20 View how we use the printing chain to lift the mold:

View how we use the printing chain to lift the mold:

If you need business consultation, please contact us